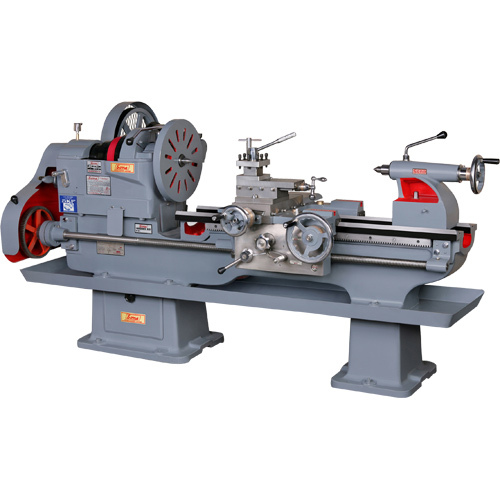

Heavy Duty Precision Lathe Machine

Product Details:

- Product Type Horizontal

- Material Metal

- CNC Or Not Normal

- Automatic Grade Semi Automatic

- Control System Human Machine Interface

- Max. Swing Diameter 900 Millimeter (mm)

- Voltage 220-440 Volt (v)

- Click to View more

Heavy Duty Precision Lathe Machine Price And Quantity

- 235000 INR/Unit

- 1 Unit

Heavy Duty Precision Lathe Machine Product Specifications

- Yes

- Horizontal

- GREY OR GREEN

- Lower Energy Consumption High Efficiency Low Noise Simple Control High Performance Stable Performance

- Normal

- Human Machine Interface

- 900 Millimeter (mm)

- 220-440 Volt (v)

- 2540 x 1450 x 1300 Millimeter (mm)

- Semi Automatic

- 1350 Kilograms (kg)

- Metal

Heavy Duty Precision Lathe Machine Trade Information

- Cash Advance (CA) Cash in Advance (CID)

- 10 Unit Per Month

- 15 Days

- Lathe Machine is Completely Plastic Wrapped with Stretch Roll, then duly Gunny Packed for Safety in Transport.

- Asia Australia Central America North America South America Eastern Europe Western Europe Middle East Africa

- All India

Product Description

SALIENT FEATURES OF "SONA" HEAVY DUTY PRECISION LATHE.

01. Heavy Duty Lathe Bed is Induction Hardened Bed. Design of the Bed is extremely heavy & rigid. Bed is heavily ribbed & rigid in construction to avoid vibration. It results in more strength & accurate workmanship.

02. Main Spindle is induction hardened & double grind finished on the bearing size. Degree of the spindle grind finished. Main spindle is rigid & accurate made out of alloy steel EN-8

03. Main Spindle is mounted on 2 precision taper roller bearings which ensures precision machining, accuracy & workmanship.

04. Design of the Bed is extremely heavy & rigid. Bed is heavily ribbed & rigid in construction to avoid vibration. It results in more strength & accurate workmanship.

05. Legs are extremely heavy & robust. Internal structure is designed with heavy ribs to avoid vibration.

06. High quality helical gears are fitted. All the teeth are shaved to remove run out.

07. Precision tumbler gears are fitted & made out of steel material.

08. Tailstock spindle is hardened having external & internal degree grinding done.

09. Hand scrapping is done on Headstock, Saddle, Cross-slide, Compound Set, Tool Post, Tail Stock, etc. for proper & rigid seating of component which avoids vibration.

10. All screw nuts are made out of Gun Metal for minimum wear & tear.

11. Support is given to the Cross-slide Screw Rod at the back side of carriage.

12. All the major parts like Head Stock, Saddle, Cross-slide, Compound Set, Tool post, Tailstock, Helical Gears, Pulley Sets etc. are extremely heavy & rigid for better performance of the lathe.

13. Provision for bearings is available in Lead Screw, Cross-slide Screw Rod, Tail Stock etc. for smooth & easy traverse.

14. Color, Paint, Finishing & overall outlook of the machine is extremely attractive & eye catching.

15. Machine under goes strict quality control at each & every stage during production.

QUALITY CONTROL

01. Meticulous care is taken right from the selection of Raw Material, Machining, complete Fitting & Assembly, Trial & Inspection up to final dispatch of Lathe Machine.

02. Trial of the machine is taken under expert supervision & undergoes strict inspection for most accurate results, Workmanship & Accuracy.

03. Components manufactured are within close tolerance, resulting into easy inter changeability.

STANDARD ACCESSORIES:

Induction Hardened Bed

Set of Change Gears (Inch & mm)

Chuck Plate

Steady Rest

Face Plate

2 Nos. Dead Centres

Centre Adaptor

Motor Rail

Motor Pulley

Switch Plate

Tool Post Key

Belt Guard

Chip Tray

Thread Dial Indicator

OPTIONAL ACCESSORIES:

Full Norton Gear Box

Taper Turning Attachment

Triple Bearings in Head - Stock

Follow Rest

Real Tool Post

Quick Change Tool Post

Reversible Switch

V-Belt for Electric Motor

Electric Motor

Dog Chuck

True Chuck

Coolant Pump with Tank

Machine Lamp

The Sona Heavy Duty Precision Lathe Machine is a high-quality metal lathe designed for precision turning and shaping. With a voltage range of 220-440 Volt (v), this lathe machine is suitable for a variety of industrial applications. It is equipped with a Human Machine Interface control system, allowing for easy and efficient operation. The machine comes with a warranty, ensuring reliable performance and peace of mind for the user. This automatic grade lathe machine is known for its lower energy consumption and high efficiency, making it a cost-effective and reliable option for businesses. Its durable metal construction ensures long-lasting performance, making it a valuable addition to any workshop or manufacturing facility.

FAQs of Sona Heavy Duty Precision Lathe Machine: